Catalyst for acrylonitriles synthesis from potentially biobased allylic alcohol

Référence

05007-02

Mots-clés

Acrylonitrile, Allylic alcohol, Biosourced, Acrylic fibers, ABS, SAN

Statut des brevets

French priority patent application FR1353478 filed on April 17th, 2013 and entitled “Procédé de production de nitriles mettant en oeuvre un catalyseur à base d’antimoine et de fer”

Inventeurs

Sébastien PAUL

Benjamin KATRYNIOK

Franck DUMEIGNIL

Carsten LIEBIG

Wolfgang HOELDERICH

Cyrille GUILLON

Statut commercial

Exclusive or non-exclusive licenses

Laboratoire

Unité de Catalyse et Chimie du Solide (UCCS, UMR8181), Villeneuve d’Ascq, France.

Description

CONTEXT

Acrylonitrile is a monomer used in the syntheses of many polymers in Organic Chemistry. Currently commercialy available acrylonitrile originates from petrosourced propene or propane. Its synthesis is usually done with the “Sohio” process. This reaction is undergone in gas phase fluidized bed reactor under high temperature (350°C – 400°C) without water and with a bismuth and molybdene-based catalyst. However, this process uses propen whose price keeps on increasing. There is therefore a demand for a process independent from propene while still offering high yields.

TECHNICAL DESCRIPTION

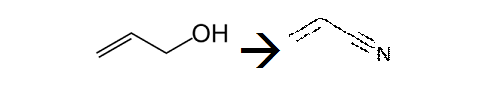

In the present work, the inventors aimed at setting up a process to synthesize acrylonitrile from allyl alcohol knowing that said raw material can also be biosourced.

They have therefore developped a antimony- and iron-based catalyst for production of nitrile (acrylonitrile) to do such target reaction.

DEVELOPMENT STAGE

- The inventors assessed the synthesis of the catalyst as well as its application for the synthesis of acrylonitrile on a laboratory scale.

- With optimal conditions, the conversion of allyl alcohol reaches 99% with a selectivity toward acrylonitrile reaching 63%.

BENEFITS

The present invention is definitely innovative as:

- It offers high yields;

- The raw material allyl alcohol can be potentially biosourced;

- And it is not based on propene reaction.

INDUSTRIAL APPLICATIONS

This first targetted application is the synthesis of acrylonitrile. This monomer can then be used for the syntheses of acrylic fibers, Acrylonitrile butadiene styrene resin (ABS), Styrene acrylonitrile resin (SAN) and nitrile rubber (NBR).

For further information, please contact us (Ref 05007-02)