Process for homogeneous cooking in microwave oven

Référence

06835-01

Mots-clés

Statut des brevets

PCT priority patent application IB2014000888 filed on May 13, 2014 and entitled “A microwave oven”

Inventeurs

Geoffroy LEROSEY

Mathias FINK

Nadège KAÏNA

Matthieu DUPRE

Statut commercial

Exclusive or non-exclusive license

Laboratoire

Institut Langevin Ondes et Images (ILOI, UMR7587), Paris, France

Description

CONTEXT

A microwave oven often provides uneven heating of the material, because the microwave radiation is not uniformly distributed inside the cavity.

The microwaves are standing electromagnetic waves inside the cavity. The electric field inside the cavity comprises high variations in intensity, forming nodes concentrating the electric energy and antinodes with very small electric energy. This leads to heating variations from one location to another location inside the cavity.

Our innovation consists in replacing the mechanical parts used to uniformize the cooking in microwave ovens by electronic ones. This presents the advantages of a better/faster cooking, a slimmer design of the oven interior and an improved energy consumption

TECHNICAL DESCRIPTION

Usually, homogenization is obtained by a turntable device to rotate the material inside the cavity (see for example patent application US2 2006/151491).

To avoid a turntable inside the cavity, patent application US 2005/184067 and US 2006/289534 disclose the use of a stirrer and a rotating antenna in the waveguide so as to change the source electromagnetic field, thereby changing the positions of the standing microwaves.

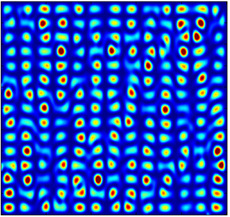

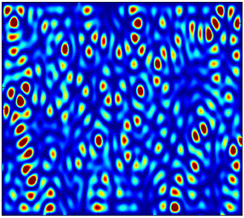

Both solutions have been invented in order to solve a major problem encountered in microwave ovens. Because they are a cavity for electromagnetic waves, the latter establish eigenmodes inside the oven, that is, a static field pattern which presents maxima and minima of electric (or magnetic) field, as sketched in Figure 1 where we map the electric energy in a 2 dimensional cavity. Since the heating of material depends on the local electric energy, minima of electric field imply a low heating while maxima induce a high one.

For this reason microwave ovens use either turntables to move the food through the minima or maxima, such that the heating is more uniform, or mode stirrers which are supposed to change the positions of the maxima and minima while the food is static, for the same reason. Both solution present problems; the turntable leaves some food unmoved, while the mode stirrer, if not big enough, does not change the mode in the microwave oven drastically enough to homogenize the heating. Moreover, both solutions imply the use of mechanical and bulky parts which take room and present a cost. Finally, both solutions, because they require to use a motor placed outside of the cavity, requires the use of complex chokes/costly in order to prevent microwaves from leaking out of the oven.

Our solution does not require the use of any mechanical or bulky part nor of chokes. The idea is to modify the mode inside the microwave oven by changing

the boundary conditions of the cavity. This can be realized by turning some of the boundaries from a metal, which is an almost perfect electric conductor, to its magnetic equivalent, that is, a perfect magnetic conductor.

Changing such boundaries can be done very easily with planar and electromagnetically tunable elements. Then, if a set of N of those elements are placed inside a microwave oven, one can change the state of each of these elements from electric to magnetic over time, either randomly or in a more regular way (amongst 2^N potential solutions), in order to modify over time the locations of maximum of electric energy, and hence to homogenize the cooking without any moving or mechanical part.

Figure 1 Example of eigenmode in a cavity (left) and same cavity with 2% of its boundaries turned to magnetic state (right)

DEVELOPMENT STAGE

A process allowing homogeneous heating without motors was developed in the Laboratory. A prototype for low energy microwaves was realized and tested inside a cavity. Simulations of electromagnetic wave propagation in a metallic cavity similar to a microwave oven have been realized which demonstrate that homogeneous heating can be realized without any mechanical parts.

BENEFITS

– Homogeneous heating

– No moving part

– Associated cost in the range of a few €

INDUSTRIAL APPLICATIONS

Microwave ovens – Industrial microwave heating

For further information, please contact us (Ref 06835-01)