CNRS Innovation - De la recherche à l'innovation depuis plus de 30 ans

0

Experts à votre service

0

Contrats d'exploitation signés depuis 2012

0

Projets accompagnés en prématuration depuis 2014

0

Start-up accompagnées par RISE depuis 2019

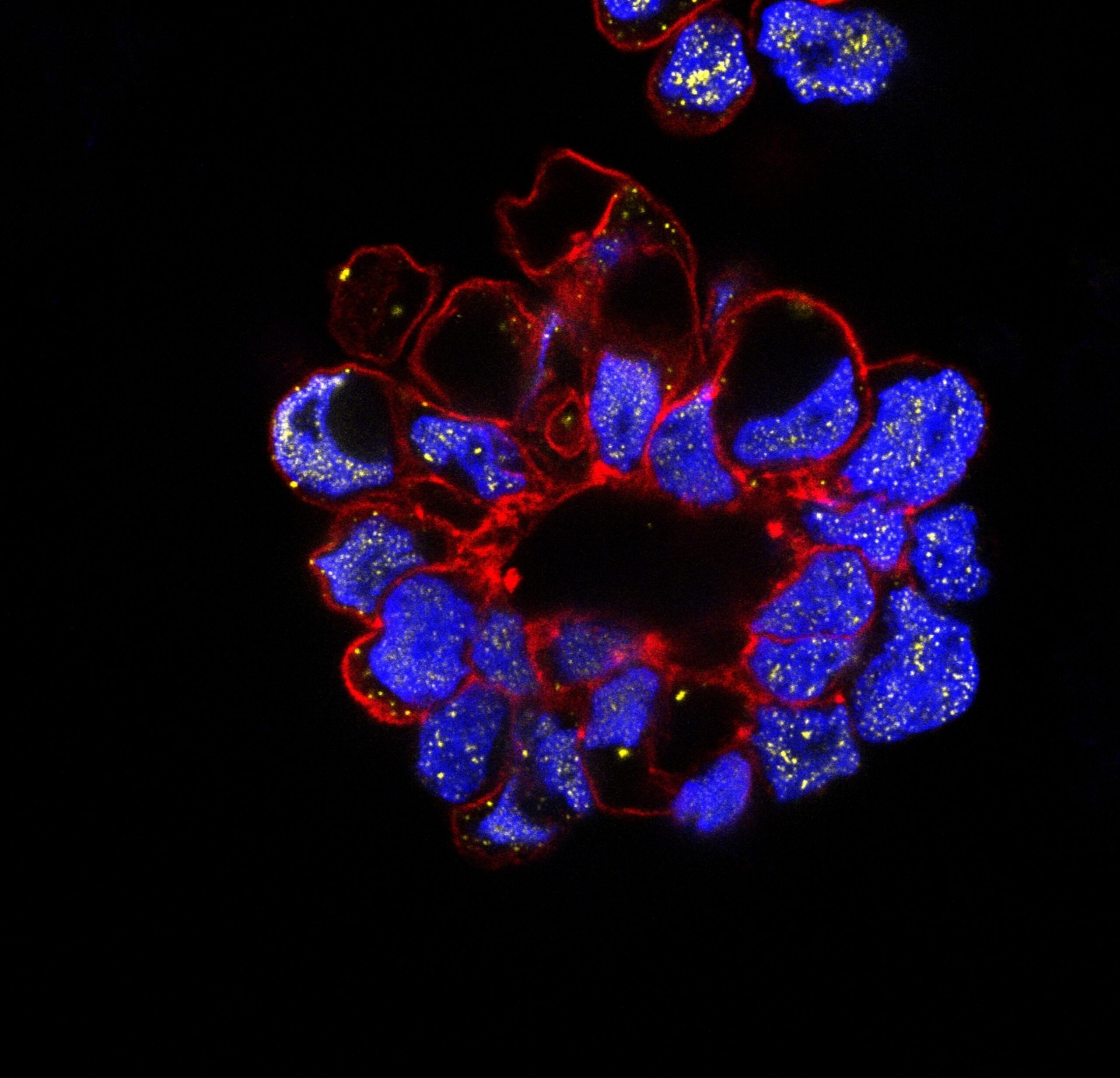

© Pascal ROBERT/OTELo/CNRS Photothèque

Notre actualité

Voir toutes les actus S’inscrire à la Lettre Innovation du CNRS La Lettre Innovation

06 mai 2024

Aldoria : la start-up qui veille à la sécurité des satellites en orbite

Grâce à ses stations d’observation réparties dans le monde entier, la société toulousaine informe ses clients sur les risques de collision de leurs satellites. Elle a levé 10 millions…

Lire la suite

06 mai 2024

Tafalgie Therapeutics : une nouvelle génération de molécules antidouleurs alternatives aux opioïdes ?

Grâce à ses années de recherches sur la protéine endogène Tafa4, la start-up pourrait développer un médicament contre les douleurs chroniques efficace et sans effets secondaires.

Lire la suite

06 mai 2024

HEPHAISTOS-Pharma : un immunostimulant pour guérir des cancers aujourd’hui incurables

La start-up HEPHAISTOS-Pharma, présente au salon VivaTech 2024, développe une molécule capable d’aider le système immunitaire à lutter efficacement contre les cellules tumorales. Et les…

Lire la suiteDonnez vie à votre projet de start-up dans les meilleures conditions

découvrez notre programme

d’accompagnement à la création de start-up

Des experts passionnés au service de l'innovation

CNRS Innovation fait converger les talents et les énergies nourries par la pluralité des profils : diplômes combinés avec expérience et savoir-faire constituent une équipe d’excellence.