Integrated magnetometer and its manufacturing process

Référence

03215-01

Mots-clés

Statut des brevets

French priority patent application n° FR1000369 filed on January 29, 2010 and entitled » Magnétomètre intégré et son procédé de fabrication »

Inventeurs

GAUDIN Gilles

Alain SCHUHL

Philippe SABON

Pierre-Jean ZERMATTEN

François MONTAIGNE

Statut commercial

Exclusive or non-exclusive license

Laboratoire

SPINTEC, (UMR 8191) in Grenoble, France and Institut Jean LAMOUR , (UMR7198) in Nancy, France.

Description

CONTEXT

More and more general public mobile devices such as watches, mobile phone, GPS, … include an electronic compass to find their orientation in space. They provide advanced navigation capabilities, for example to indicate the direction in which a person or a vehicle is moving when GPS is not available, or for emerging smart location-based services. The 3D magnetometers market is now rapidly growing and there is a current need for smaller, more sensitive and energy-saving magnetic sensors. However present technologies, which are based on high sensitivity magnetoresistive sensors, do not allow the fabrication of fully integrated 3D magnetometers: a three axis magnetometer can only be fabricated using a hybrid scheme composed of at least two non-coplanar substrates. This leads to fragile and bulky devices with high manufacturing cost and a sensitivity limited by systematic errors due to the manufacturing procedure. In addition, these magnetoresistive sensors suffer from the need for a compensation of their intrinsic thermal drift.

TECHNICAL DESCRIPTION

This invention describes a 3D magnetometer offering innovating solution to these problems.

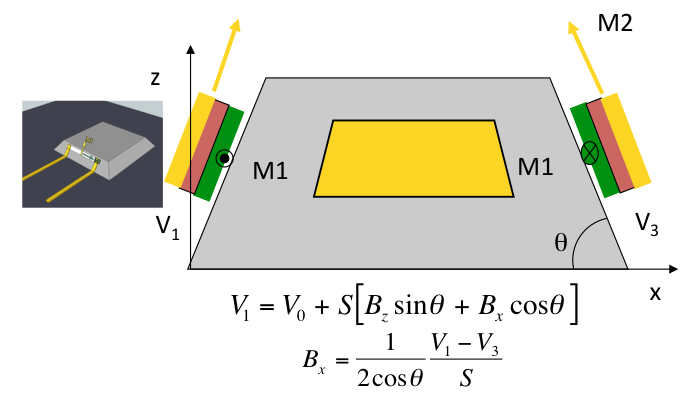

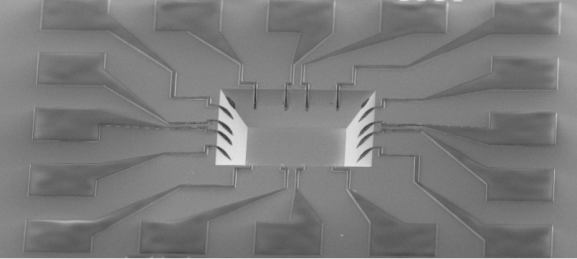

One example of realization can be obtained starting by chemically etching a silicon substrate in KOH. The resulting pyramidal cavity or protuberance presents inclined plane faces whose angle with the substrate is perfectly defined by the crystalline axes. The deposition of a magneto-resistive layer and its patterning results in at least four identical sensors placed on the four inclined faces. These sensors are opposite one another in pairs. Each of them is sensitive to the component of the external magnetic field parallel to the face on which it is placed. The magnetic field component can be deduced from the voltage measurements as schematically shown on the figure below (left). The right part of this figure shows a SEM image of one realization with the different contact pads.BENEFITS

In this magnetometer, the three components of the magnetic field are simultaneously deduced by magneto resistive sensors integrated on the same substrate. Since the sensors are all strictly identical with the same sensitivity and thermal drift, they significantly simplify the drift compensation that can be otherwise very energy consuming. This type of sensor thus offers higher compactness and sensitivity combined with reduced consumption and a much simpler manufacturing process.

It will be easily inserted into a mobile device to be used as an integrated low power micro-compass.

Principle of the field components measurement.

Example of realization

INDUSTRIAL APPLICATIONS

The market for 3D magnetometer is currently experiencing a strong growth and can find applications in various fields.

Their main application relates to consumer electronics as for example integrated compass in mobile devices for advanced navigation and intelligent interactive services depending on the position; virtual reality with e.g. integration in advanced joysticks or in goggles for user orientation in space; … They found also application in security/defense (advanced mobile equipment of soldiers) or in medical (range of motion measurement in rehabilitation process, …).

DEVELOPMENT STAGE

A first generation has been fabricated and tested. It validates the principle and already shows a good sensitivity despite a magnetic arrangement of the sensor layer far from optimal. Developments and optimization of the magnetic layers are in progress.

For further information, please contact us (Ref 03215-01)

Besoin de plus d'informations ?

Nous contacterTechnologies Liées

-

18.02.2014

StéréoPhotométrie: The roughness measuring software

Dispositifs & Instruments 05413-01

-

04.10.2013

Protein macroarrays for autoantibodies detection

Dispositifs & Instruments, Diagnostic médical 04731-01

-

03.10.2013

Steering aid system for altitude and horizontal speed, perpendicular to the vertical, of an aircraft and aircraft equipped therewith

Dispositifs & Instruments 85442-01