Environmentally-friendly processes to breakdown elastomers leading to reusable telechelic oligomers with controlled structures

Référence

05717-01; 03489-01

Mots-clés

Rubber, Elastomer, Oligomers, Telechelic, Metathesis, Grubbs

Statut des brevets

PCT priority patent application PCT/FR2010/050292 filed on February 19, 2010 and entitled “Procédé de préparation d’oligomères téléchéliques d’intérêt à partir de déchets pneumatiques”

French priority patent application FR1361980 filed on December 3rd, 2013 and entitled “Procédé de fabrication d’oligomères téléchéliques fonctionnalisés”

Inventeurs

2010 patent

Faten SADAKA

Irène CAMPISTRON

Albert LAGUERRE

Jean-François PILARD

2013 patent

Jean-François PILARD

Arnaud NOURY

Isabelle DEZ

Annie-Claude GAUMONT

Ali MOUAWIA

Statut commercial

Exclusive or non-exclusive license

Laboratoire

Institut des Molécules et Matériaux du Mans (IMMM, UMR6283), Le Mans, France.

Laboratoire de Chimie Moléculaire et Thioorganique (LCMT, UMR6507), Caen, France.

Description

CONTEXT

The different methods that are currently used nowadays to recycle elastomers are known to be expensive, constraining (high pressure and temperature requirements) and not environmentally-friendly.

Among the different ways that are available, incineration is one the most widely used. Other methods involve mechanical or even chemical transformations. Nevertheless, none of these methods fully offers full satisfaction.

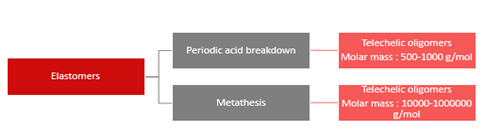

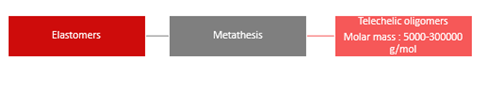

Among the available chemical transformation, one can cite the breakdowns of elastomers into telechelic oligomers which can advantageously lead to various polymers.

However, in order to have a fully satisfying breakdown alternative, there is clearly a demand for an efficient environmentally-friendly way to do so.

TECHNICAL DESCRIPTION

In the present work, the inventors have developed three ways to do the breakdown:

- 2010 patents – Organic solvent

- 2013 patents – Ionic liquid

DEVELOPMENT STAGE

- 2010 patents-related process have been fully assessed on a laboratory scale with natural rubber: polyisopropene (NR); as well as synthetic rubbers: polyisopropene (IR), polybutadiene (BR), Styrene-butadiene (SBR), butadiene-acrylonitrile (NBR).

- 2013 patents-related process have been fully assessed on a laboratory scale with natural rubber: polyisopropene (NR); and the following synthetic rubbers: SR, SBR, NBR, and EPDM…

BENEFITS

The processes used in the present work are efficient, non expensive, non constraining and environmentally-friendly. It also has the benefit of getting oligomers with a controlled structure using three complementary methods.

Noticeably, the use of liquid ionic in the 2013 patents is clearly an advantage for the breakdown of elastomers into high molar mass oligomers.

INDUSTRIAL APPLICATIONS

The main application concerns the recycling of tires as well as other elastomer-based products. On a second level, the resulting telechelic oligomers can be used in numerous applications. For example, they can be used in bactericides, foams, rubber formulation and anti-fouling coating.

For further information, please contact us (Ref 05717-01 / 03489-01)