CNRS Innovation - De la recherche à l'innovation depuis plus de 30 ans

0

Experts à votre service

0

Contrats d'exploitation signés depuis 2012

0

Projets accompagnés en prématuration depuis 2014

0

Start-up accompagnées par RISE depuis 2019

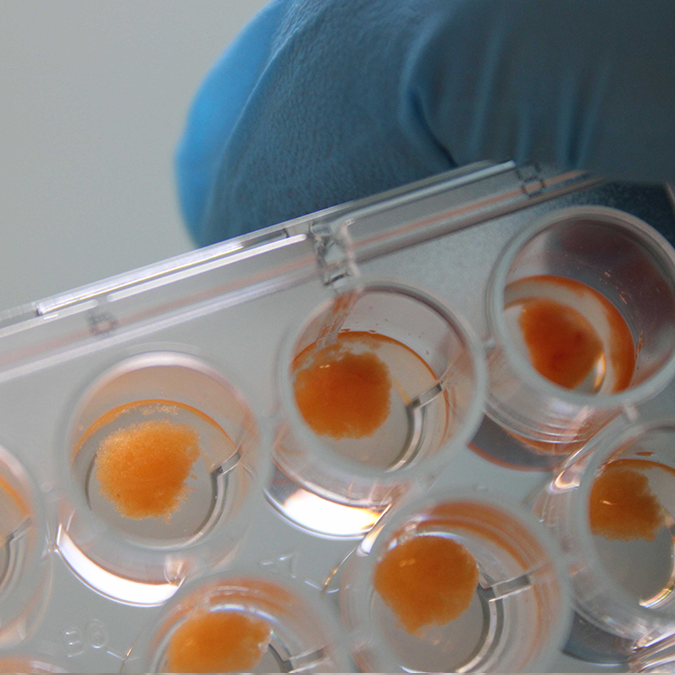

© Jean-Claude MOSCHETTI / SPCTS / CNRS Photothèque

Notre actualité

Voir toutes les actus S’inscrire à la Lettre Innovation du CNRS La Lettre Innovation

27 mars 2024

Les levées de fonds du mois de février 2024

Chaque mois, retrouvez les levées de fonds des entreprises issues des laboratoires sous tutelle du CNRS.

Lire la suite

22 mars 2024

ExAdEx-Innov : Une biotechnologie novatrice pour l’étude de la graisse humaine

Conserver de la graisse humaine au plus près de son état d’origine en culture est une difficulté en soi. Grâce à sa technologie, c’est le défi que relève ExAdEx-Innov. Cette start-up…

Lire la suite

22 mars 2024

Comment la découverte de chercheurs révolutionne la microscopie de super-résolution

Grâce à une durée de vie grandement rallongée, les tampons permettant aux fluorophores de clignoter en milieu aqueux, conçus par une équipe de l’Institut NeuroMyoGène de Lyon, améliorent…

Lire la suiteDonnez vie à votre projet de start-up dans les meilleures conditions

découvrez notre programme

d’accompagnement à la création de start-up

Des experts passionnés au service de l'innovation

CNRS Innovation fait converger les talents et les énergies nourries par la pluralité des profils : diplômes combinés avec expérience et savoir-faire constituent une équipe d’excellence.